How much do you know about floor stamp mold and its use process?

News 2022年8月11日 262

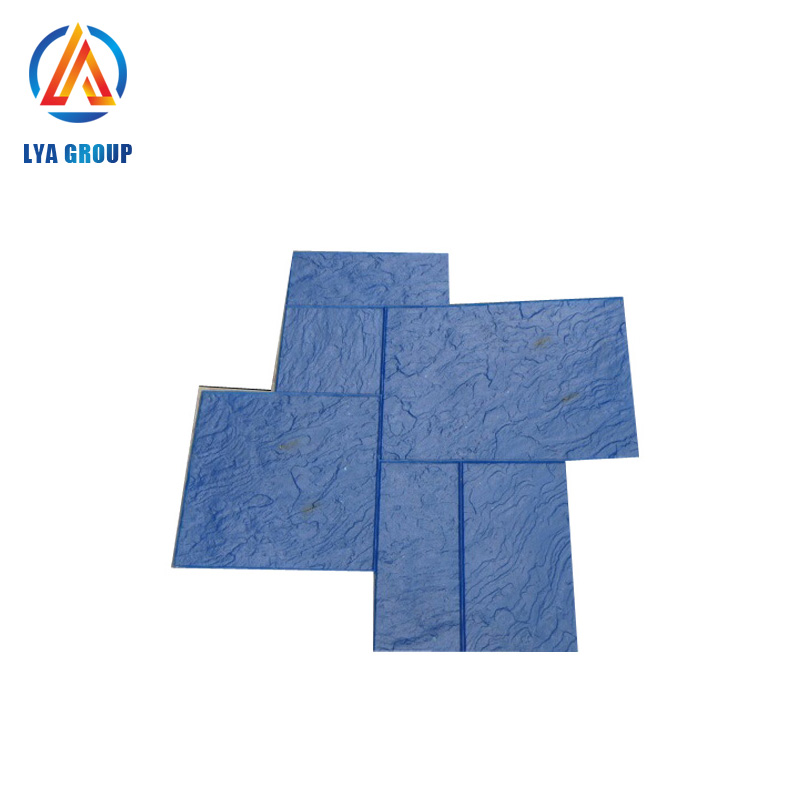

As a decorative mold for embossing the ground texture, the floor stamp mold is widely welcomed by customers at home and abroad. Not only does it have a variety of designs for customers to choose from, but also the operating procedures are convenient, simple and fast.

Let me briefly introduce the floor stamp mold for everyone.

1. The material of the floor stamp mold is PU, that is, polyurethane. The mold thickness is 2-3cm, divide into soft mold and hard mold. The ordinary hardness of hard mold is 80 degrees, and the hardness of soft mold is 50 degrees. The soft mold is used to suppress the corners of the ground project, and the matching mold with 5 hard and 1 soft will greatly speed up the work efficiency.

2. When using the floor stamp mold, the tools you need include a large spatula, a small spatula, a PU pier, an edge cutter, a seam repair tool, etc.; during construction, you need to use a flat mixer, a trowel, etc.; And the need to use additives, such as hardener agent, release powder, brightening agent. All products are ready well to help you step by step during the construction process, with ease.

With these configurations, how do we construct it? Is the process simple?

1. Pouring concrete on the ground and level it

2.Scattering color floor hardener agent,3-5kg for 1 square meter, and make it same level;

3. Sprinkling the strengthening material twice, compact it;

4.Sacttering color release powder, 0.15-0.2kg for 1 suqare meter;

5.Printing the road with stamp mold;

6.Washing the floor and spray finishing protective agent after 3 days,0.15-0.3kg for 1 suqare.

These are the whole process of construction, very simple and easy to operate, we can sell all the above-mentioned additives, such as hardener agent, release powder, brightening agent. If you need, we also provide non-free technology transfer.

If you want to know more, please contact us as soon as possible.

To provide you with one-stop service, welcome your consultation.